Training Root Cause Analysis for Leaders in the Geothermal industry |

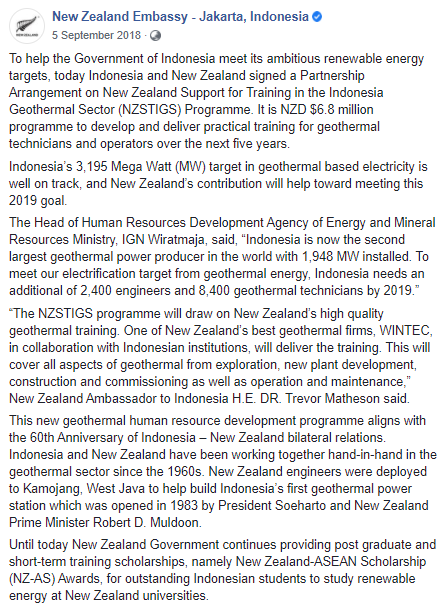

| Sebelah ini kalau saya buka di laman FB nya New Zealand Embassy, tentang program partnership melalui program New Zealand Support for Training in the Indonesia Geothermal Sector (NZSTIGS). Program NZD $6,8 juta ini bertujuan untuk mengembangkan dan memberikan pelatihan praktis bagi teknisi dan operator Geothermal selama lima tahun ke depan. “Program NZSTIGS akan memanfaatkan pelatihan Geothermal berkualitas tinggi di Selandia Baru. WINTEC [salah satu perusahaan Geothermal terbaik di NZ], bekerja sama dengan institusi Indonesia, untuk program pelatihan ini. Trus program pelatihan mencakup semua aspek panas bumi mulai dari eksplorasi, pengembangan pembangkit baru, konstruksi dan commissioning serta operasi dan pemeliharaan. |

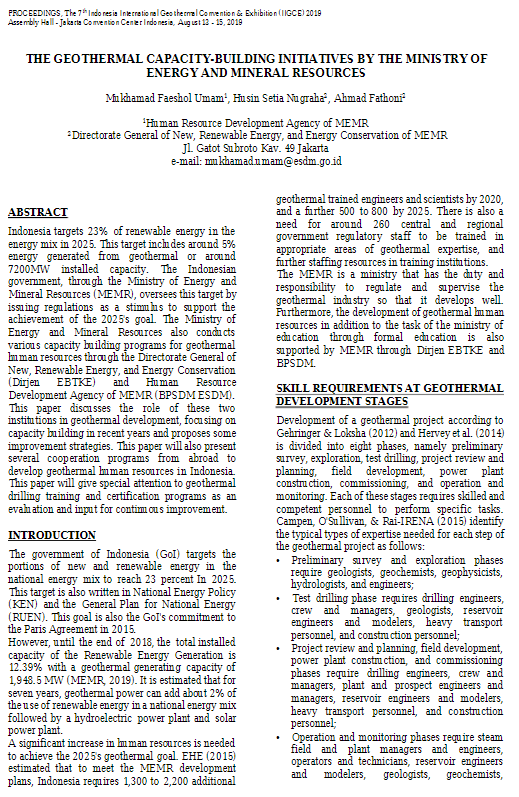

Saya ada baca sebuah paper proceeding mengenai project "Geothermal Competencies" yang mungkin juga berkaitan dengan latar belakang program kerjasama pelatihan ini.

| Kesimpulan dan saran paper tersebut diantaranya "This paper is a review of competency needs in the geothermal industry, regulations related to the development of the geothermal human resource, capacity building programs by the MEMR, and support from stakeholders. It can be concluded that to meet geothermal human resource needs, both quality and quantity, all parties, both government, companies, and educational institutions, are needed. The government, through the Director General of EBTKE and the Human Resource Development Agency, has carried out various roles, including the preparation of SKKNI and training in the geothermal field." Saya ingin banget bisa kerja seperti dulu, kasih saya ikut project-project, apalagi bisa dijadiin research.. proceedings.. mantaplaah... |

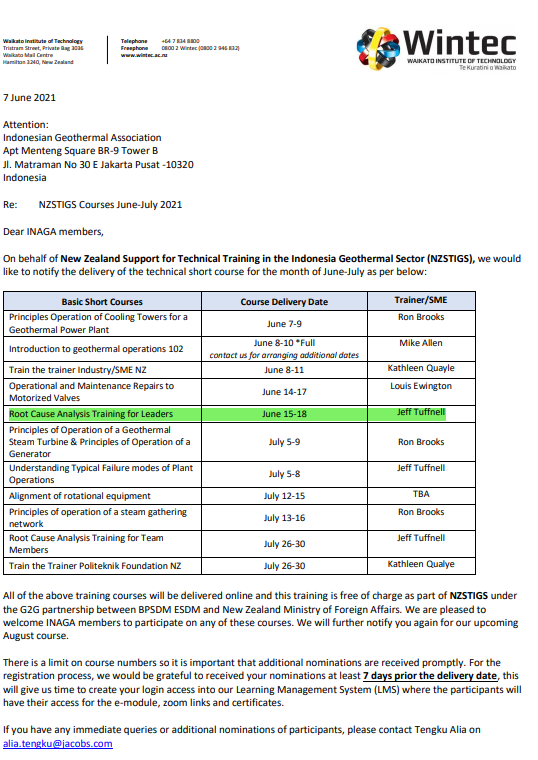

Setelah cek cek cek saya kirim email daftar. Waktunya pas jam kerja sih, 3 jam an selama 4 hari. Tapi worthed lah ya,, karena 3 jam an juga saya ga ambil cuti, cuma ijin aja biar ga diganggu pas waktu training, change waktu kerja. kan WFH.. asal kerjaan tetap selesai lah ya..

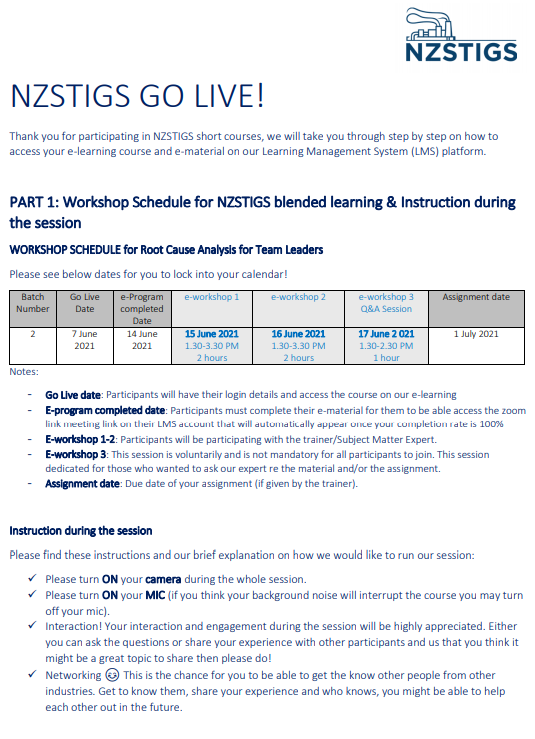

Dari pamflet pengumuman training itu masih adalah topik yang bisa saya ikut; kalau topik lain udah technical banget, tuing tuing nanti saya pas training. Trus setelah daftar training by email, bakal dapat email konfirmasi lebih lanjut. Di email konfirmasi dikasih juga panduan ikut training ini, dapat akses login details; e-learnning dan e-material melalui LMS

Dari pamflet pengumuman training itu masih adalah topik yang bisa saya ikut; kalau topik lain udah technical banget, tuing tuing nanti saya pas training. Trus setelah daftar training by email, bakal dapat email konfirmasi lebih lanjut. Di email konfirmasi dikasih juga panduan ikut training ini, dapat akses login details; e-learnning dan e-material melalui LMS

Training ini online interactive gitu, trus ada break room nya buat diskusi. Pas diskusi ini kemarin sih dibagi jadi 2 break room, dikasih bahan exercise untuk diskusi sama trainernya trus dicompile per team nya n di present. Selain diskusi ini ada juga assignment, Pe ER gitu tiap harinya. Trus, assignment final dikirim terakhir kalau pass baru dapat sertifikat trainingnya.

Saat sesi training saya ikut ini, pesertanya banyak dari PGE, dari akademisi ada juga trus dari konsultan ELC dua orang saya sama Pak Prihatmaka.

Saat sesi training saya ikut ini, pesertanya banyak dari PGE, dari akademisi ada juga trus dari konsultan ELC dua orang saya sama Pak Prihatmaka.

berikut brief sedikit tentang RCA, tapi ga saya translatin lah ya..

RCA is a process used to identify the underlying cause(s) of an equipment failure or breakdown. RCA involves;

• Analysing all possible causes for an equipment failure

• Selecting the most probable causes

• Identifying and selecting solutions to eliminate or control the causes

• Implementing controls to ensure that solutions are sustained.

RCA is a process used to determine how and why a breakdown or equipment failure happened. The purpose of RCA is to prevent failures from happening again. RCA is sometimes known as Root Cause Failure Elimination.

The processes and systems used in RCA evolved from the quality management movement

RCA is a process used to identify the underlying cause(s) of an equipment failure or breakdown. RCA involves;

• Analysing all possible causes for an equipment failure

• Selecting the most probable causes

• Identifying and selecting solutions to eliminate or control the causes

• Implementing controls to ensure that solutions are sustained.

RCA is a process used to determine how and why a breakdown or equipment failure happened. The purpose of RCA is to prevent failures from happening again. RCA is sometimes known as Root Cause Failure Elimination.

The processes and systems used in RCA evolved from the quality management movement

Dr. W. Edwards Deming’s System of Profound Knowledge provides a framework for the thinking and actions required to improve quality, reliability, productivity and business results.

he four principles in the System of Profound Knowledge are evident in Total Quality Management and in the Toyota Production System. They ultimately form the basis for “Lean Thinking”. The System of Profound Knowledge brings together Dr. W. Edwards Deming’s theories and teachings on quality, management and leadership into four interrelated areas:

1. Appreciation for a system

In RCA, appreciation for a system requires us to develop an understanding of the interdependent components. We need to understand how components work together and the impact that changes will have on the system. . A failure in one area will have an impact in other parts of the system.

2. Knowledge of variation

RCA requires us to ask why a system has failed. More importantly, it requires us to find the right answers and take the right course of action. It is not possible to understand how a system has failed without an understanding of the systems variation.

3. Theory of knowledge

Dr. Deming stated that, theories, hypotheses and beliefs must be tested using data and experiments to understand what is actually happening. Effective RCA uses data and not opinions or theories that can often lead to an incorrect diagnosis.

4. Psychology

In RCA the facilitator must also have a good understanding of people. Not only of the skills and knowledge that they bring to the RCA sessions, but also the bias and potential defensiveness that they can bring. Teamwork is essential for a quality RCA.

he four principles in the System of Profound Knowledge are evident in Total Quality Management and in the Toyota Production System. They ultimately form the basis for “Lean Thinking”. The System of Profound Knowledge brings together Dr. W. Edwards Deming’s theories and teachings on quality, management and leadership into four interrelated areas:

1. Appreciation for a system

In RCA, appreciation for a system requires us to develop an understanding of the interdependent components. We need to understand how components work together and the impact that changes will have on the system. . A failure in one area will have an impact in other parts of the system.

2. Knowledge of variation

RCA requires us to ask why a system has failed. More importantly, it requires us to find the right answers and take the right course of action. It is not possible to understand how a system has failed without an understanding of the systems variation.

3. Theory of knowledge

Dr. Deming stated that, theories, hypotheses and beliefs must be tested using data and experiments to understand what is actually happening. Effective RCA uses data and not opinions or theories that can often lead to an incorrect diagnosis.

4. Psychology

In RCA the facilitator must also have a good understanding of people. Not only of the skills and knowledge that they bring to the RCA sessions, but also the bias and potential defensiveness that they can bring. Teamwork is essential for a quality RCA.

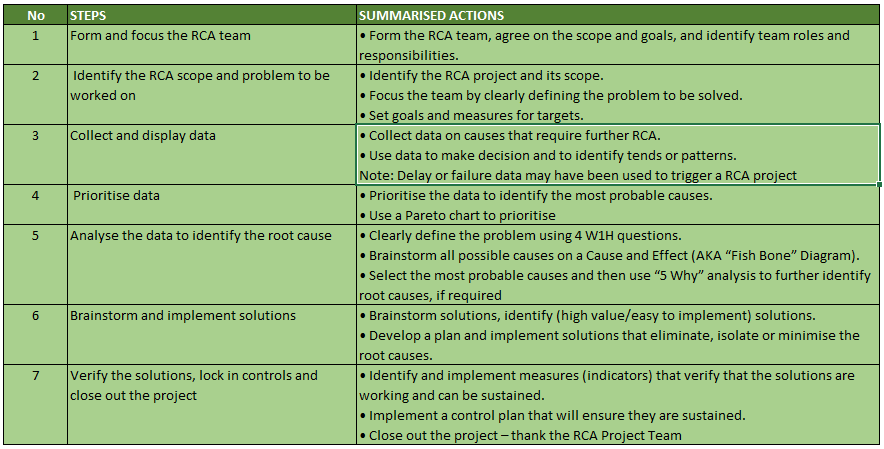

RCA PROCESS STEPS - OVERVIEW

There are different RCA methods. Each RCA process may use different terms and definitions but the fundamental steps remain the same. The seven steps listed in the table below are common to most RCA processes.

There are different RCA methods. Each RCA process may use different terms and definitions but the fundamental steps remain the same. The seven steps listed in the table below are common to most RCA processes.

berikut beberapa contoh tools yang digunakan sewaktu melakukan RCA

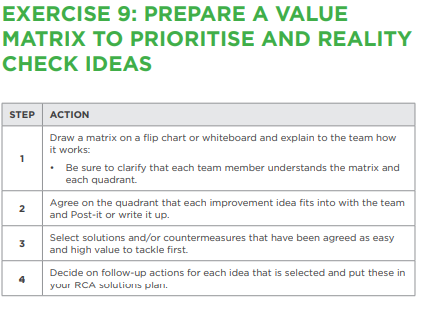

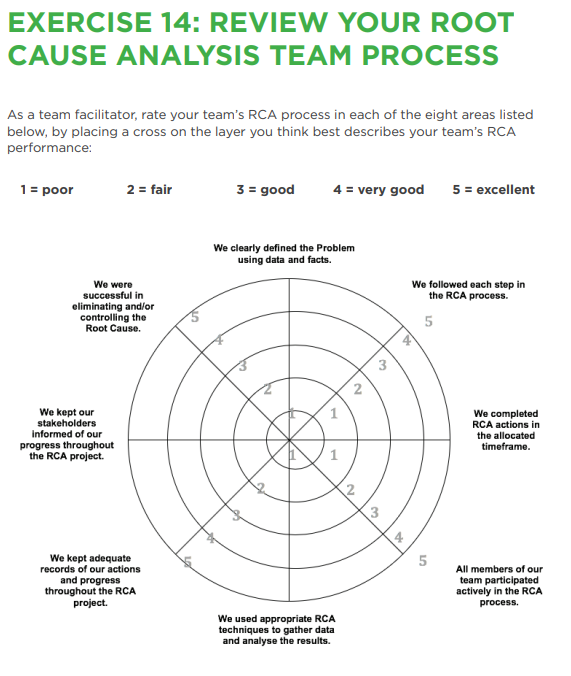

Berikut adalah contoh exercise selama training, belum lagi yang final assignment..

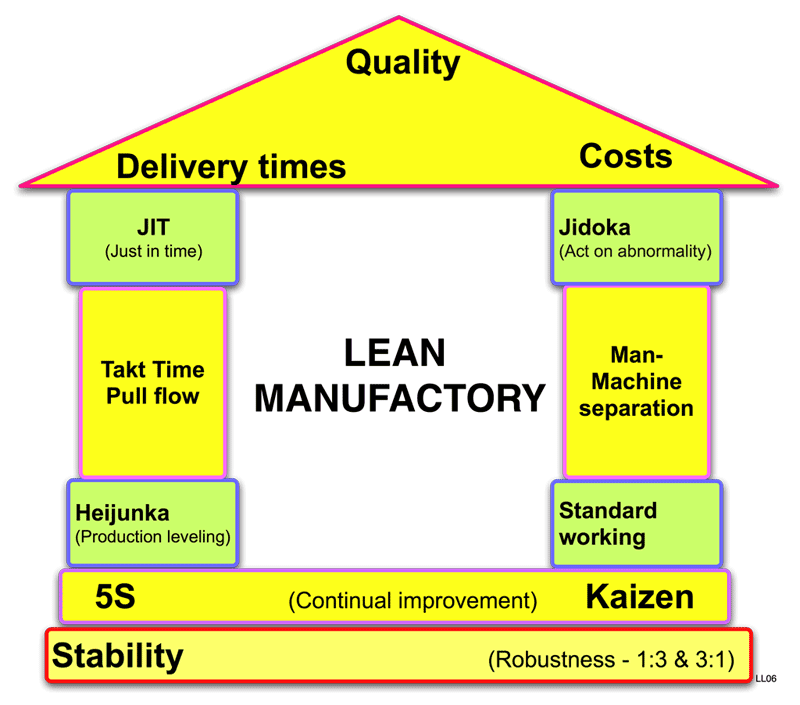

Two weeks Basic Lean Training

jaman dulu, tempat saya kerja pertama, PT Shyang Yao Fung, saya pernah iku training Lean Manufacturing selama 2 minggu [2 minggu.. cuma training n ngerjain project training aja.. kereenlah].

Training ini inhouse di perusahaan, yang ngadakan n jadi trainernya dari buyer [Adidas CI]. Disini saya belajar banyak hal tentang manufacturing production dkk dkk. Wuuuihh itu training mantep bangetlah.

Nantilah saya update postingan ini, saya buka dulu laptop lama, karena ga adalaaah filenya laptop yang sekarang saya buat nulis ini...

Saya rindu training, merasakan mata berbinar jantung berdegup ingin tau ini itu saat belajar hal yang baru.. apalagi training yang gratisan.. hahahha..

Training ini inhouse di perusahaan, yang ngadakan n jadi trainernya dari buyer [Adidas CI]. Disini saya belajar banyak hal tentang manufacturing production dkk dkk. Wuuuihh itu training mantep bangetlah.

Nantilah saya update postingan ini, saya buka dulu laptop lama, karena ga adalaaah filenya laptop yang sekarang saya buat nulis ini...

Saya rindu training, merasakan mata berbinar jantung berdegup ingin tau ini itu saat belajar hal yang baru.. apalagi training yang gratisan.. hahahha..

0 Comments

- Tools & Equipment

- Safe zone position

- Permit to work

- Isolation

- Confined Space

- Lifting Operation

- Fit To Work

- Working at Height

- Personal Flotation Device

- System Over bride

- Asset Integrity

- Driving Safety

- Seiri (Sort)

- Seiton (Set in order)

- Seiso (Shine)

- Seiketsu (Standardize)

- Shitsuke (Sustain)

- Safety

WorkLedge

means work knowledge or workplace Knowledge

Knowledge work is all about problem-solving and requires both convergent and divergent thinking to answer all the simple and complex questions that arise in daily work.

Knowledge workers would be expected to innovate often, routinely coming up with new and better ways of doing things.

Workplace knowledge represents the intersection of three key trends: the leverage of intellectual capital, the virtualization of the workplace and the shift from hierarchical to organic models of management. The focus is on knowledge as the primary source of competitive advantage- Gartner.

Knowledge hunt!

Upskilling HSSE Officer Training

Merupakan pembekalan kepada HSSE Officer agar memiliki kompetensi minimal yang sama.

Part 1

Membahas mengenai dasar K3 dan Corporate Live Saving rules:

Part 1

Membahas mengenai dasar K3 dan Corporate Live Saving rules:

Basic Lean Training Manufacturing

Berisikan pengalaman saya mengikuti training lean manufacturing selama 2 minggu.

Membahas mengenai konsep Lean, TPM, muda, mura, muri, 6S, konsep kaizen, continous improvement, etc.

Training super padat dan seru, yang menberikan saya baseline yang sangat bagus dan kuat dalam hal productivity, quality dan audit.

Membahas mengenai konsep Lean, TPM, muda, mura, muri, 6S, konsep kaizen, continous improvement, etc.

Training super padat dan seru, yang menberikan saya baseline yang sangat bagus dan kuat dalam hal productivity, quality dan audit.

3M's of Lean:

Muda (waste);

Mura (inconsistency);

Muri (unreasonableness)

Muda (waste);

Mura (inconsistency);

Muri (unreasonableness)

6S's of Kaizen

RCA FOR LEADERS

Satu training yang saya ikuti di tahun ini, oleh NZSTIG's dengan trainernya Jeff Tuffnell.

Program New Zealand Support for Training in the Indonesia Geothermal Sector (NZSTIGS) senilai NZD $6,8 juta yang bertujuan untuk mengembangkan dan memberikan pelatihan praktis bagi teknisi dan operator Geothermal selama lima tahun ke depan.

“Program NZSTIGS akan memanfaatkan pelatihan Geothermal berkualitas tinggi di Selandia Baru. WINTEC [salah satu perusahaan Geothermal terbaik di NZ], bekerja sama dengan institusi Indonesia, untuk program pelatihan ini.

Program New Zealand Support for Training in the Indonesia Geothermal Sector (NZSTIGS) senilai NZD $6,8 juta yang bertujuan untuk mengembangkan dan memberikan pelatihan praktis bagi teknisi dan operator Geothermal selama lima tahun ke depan.

“Program NZSTIGS akan memanfaatkan pelatihan Geothermal berkualitas tinggi di Selandia Baru. WINTEC [salah satu perusahaan Geothermal terbaik di NZ], bekerja sama dengan institusi Indonesia, untuk program pelatihan ini.

K3L DIRUMAH

K3L dalam rumah tangga percaya atau tidak seringkali disepelekan dan dianggap biasa saja.

Kalau di perusahaan ada tim HSE yang memonitor, bagaimana dengan rumah kita? sudahkah kita memperhatikan aspek-aspek K3L bagi keluarga terdekat kita?

Tentu saja artkel ini suatu saat akan saya update agar lebih eye cathcing lagi, wait yaa...

Kalau di perusahaan ada tim HSE yang memonitor, bagaimana dengan rumah kita? sudahkah kita memperhatikan aspek-aspek K3L bagi keluarga terdekat kita?

Tentu saja artkel ini suatu saat akan saya update agar lebih eye cathcing lagi, wait yaa...

UJI KOMPETENSI AUDITOR LINGKUNGAN

Mengulas tentang perjalanan saya mendapatkan C.EA (Certified Environmental Auditor).

Mulai dari persyaratan administrasi, bukti pengalaman audit, ujian tulis, wawancara, hingga terregister di web nya klhk sebagai auditor lingkungan.

Mulai dari persyaratan administrasi, bukti pengalaman audit, ujian tulis, wawancara, hingga terregister di web nya klhk sebagai auditor lingkungan.

PELATIHAN AUDITOR LINGKUNGAN

Mengulas mengenai Pelatihan auditor lingkungan yang saya ikuti di PSLH UGM.

Pelatihan ini padat, dengan tujuan utama menjadikan peserta sebagai auditor lingkungan yang handal dan kompeten.

Kompeten dilegalkan dengan mengikuti uji kompetensi.

Pelatihan ini akan memberikan kepercayaan diri bagi kita sebagai seorang auditor yang kompeten dan kredibel, telah dilatih dan diajar oleh lembaga dan gutu-guru yang mumpuni dan memang ahli dalam bidang lingkungan.

Pelatihan ini padat, dengan tujuan utama menjadikan peserta sebagai auditor lingkungan yang handal dan kompeten.

Kompeten dilegalkan dengan mengikuti uji kompetensi.

Pelatihan ini akan memberikan kepercayaan diri bagi kita sebagai seorang auditor yang kompeten dan kredibel, telah dilatih dan diajar oleh lembaga dan gutu-guru yang mumpuni dan memang ahli dalam bidang lingkungan.

Archives

November 2024

December 2023

November 2023

June 2023

March 2023

December 2022

July 2022

February 2022

January 2022

July 2021

May 2021

April 2021

January 2020

July 2019

April 2019

March 2019

January 2019

September 2018

March 2018

Categories

|

this page replacing my old blog page: https://mariacreativity.blogspot.com/

|

Site powered by Weebly. Managed by Exabytes - Indonesia

RSS Feed

RSS Feed